The Tire Pressure Monitoring System (TPMS) is a critical safety feature in modern vehicles. It monitors tire pressure in real-time and alerts drivers before serious issues occur, preventing blowouts, uneven tire wear, and increased fuel consumption. When the TPMS warning light turns on, many drivers ask: how to tell which TPMS sensor is bad. This guide provides a professional, detailed, and actionable approach suitable for both car owners and technicians, covering everything from basic understanding to advanced diagnostics.

Understanding TPMS: Direct vs. Indirect

Before learning how to tell which TPMS sensor is bad, it’s crucial to know your vehicle’s TPMS type:

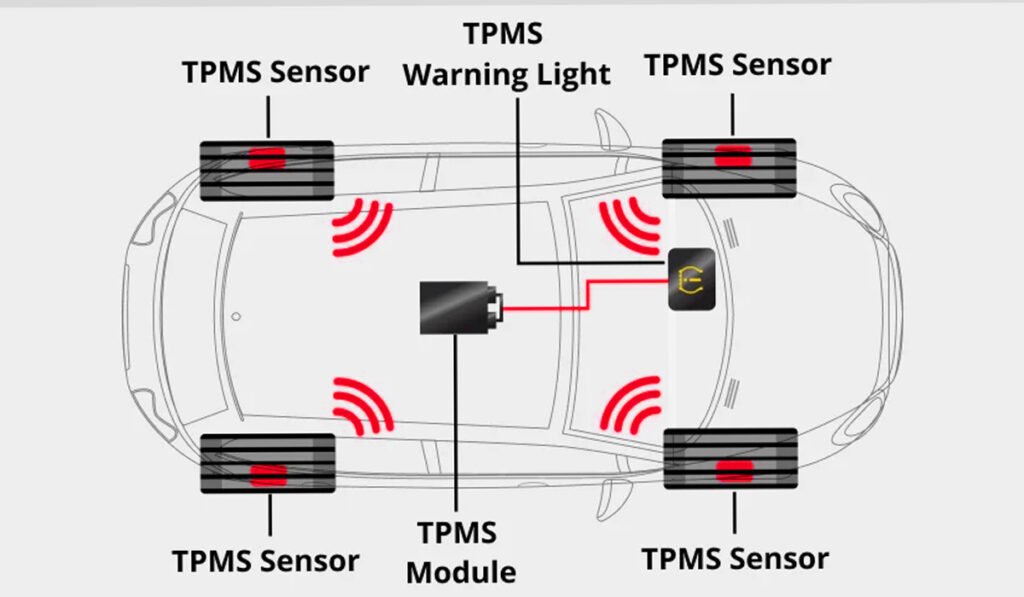

Direct TPMS (dTPMS)

Direct TPMS installs a sensor in each tire valve or hub, measuring:

- Tire pressure (PSI or bar)

- Tire temperature

- Battery status

Data is wirelessly transmitted to the vehicle ECU. Direct TPMS is precise and can pinpoint the specific faulty tire, which makes it easier to understand how to tell which TPMS sensor is bad.

Key Points:

- Most sensors have built-in batteries lasting 5–10 years

- Operates at 315 MHz or 433 MHz

- Common failures include battery depletion, physical damage, or signal interference

Related Reading: How to Choose Compatible TPMS Sensors for Your Car

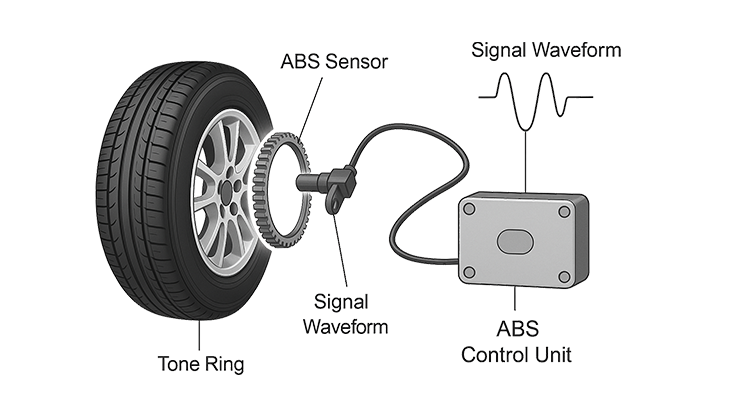

Indirect TPMS (iTPMS)

Indirect TPMS uses ABS wheel speed sensors to detect differences in tire rotation, estimating low tire pressure.

Limitations:

- Cannot identify which specific sensor is bad

- Requires system reset or calibration after tire maintenance

- Less accurate than direct TPMS

Understanding the TPMS type ensures you choose the correct method for how to tell which TPMS sensor is bad.

Common Signs of TPMS Sensor Failure

To determine how to tell which TPMS sensor is bad, watch for these symptoms:

- TPMS warning light stays on or flashes before staying solid

- Dashboard shows tire pressure as “–“, “XX”, or a fixed value

- The system cannot complete reset or relearn procedures

- Warning light intermittently illuminates while tire pressure is normal

⚠️ Safety Tip: A faulty TPMS sensor means losing the first line of tire pressure warning, increasing the risk of blowouts, longer braking distances, and reduced handling performance. Knowing how to tell which TPMS sensor is bad can prevent accidents.

Method 1: Using a Diagnostic Tool (Professional Technician Approach)

For technicians or advanced DIY users, a diagnostic tool is the most accurate way to determine how to tell which TPMS sensor is bad.

Steps:

- Connect the diagnostic device

- Recommended: Autel, Launch, Snap-on

- OEM or compatible scanners provide full functionality

- Access the TPMS module

- Navigate to “Read Data Stream” or “TPMS Status”

- Analyze real-time data

- Normal sensor: shows stable pressure, temperature, and signal strength

- Faulty sensor: shows no signal, invalid data, or abnormal readings

- Confirm sensor IDs

- Each sensor ID is stored in the ECU

- No response or ID mismatch indicates a faulty sensor

Advantages:

- Precisely locates the faulty sensor

- Can detect ECU or communication module issues

- Ideal for fleets or professional workshops

Method 2: Using a TPMS Activation Tool

A TPMS activation tool quickly tests sensors without removing tires, making it an efficient method to identify how to tell which TPMS sensor is bad.

Steps:

- Prepare the activation tool

- Common brands: ATEQ, Autel, Bartec

- Related Product: TPMS Activation Tool – Fast Sensor Diagnosis

- Activate each sensor

- Place the probe near the tire valve

- Normal sensor: returns pressure and temperature data

- Faulty sensor: no response or error

- Compare with ECU IDs

- Advanced tools read sensor IDs for matching confirmation

Advantages:

- Quick and non-invasive

- Suitable for professionals and advanced car owners

Knowing how to tell which TPMS sensor is bad using this method saves time and prevents unnecessary replacements.

Method 3: Dashboard Observation and DIY Check

Car owners can also use the dashboard to identify how to tell which TPMS sensor is bad.

Case A: Dashboard Shows Individual Tire Pressure

- Measure all tires with a digital tire gauge

- Compare readings with the dashboard:

- Values change with pressure → sensor is working

- “–” or “XX” fixed → possibly faulty

- Dynamic test: inflate or deflate ±5 PSI and observe dashboard response

Case B: Dashboard Only Shows TPMS Warning Light

- Perform system reset

- Drive 15–20 minutes to allow the system to relearn sensors

- If light remains on → one or more sensors may be faulty

- Tip: Try resetting the system yourself before visiting a workshop

Advantages:

- No specialized equipment required

- Useful for routine checks and preliminary diagnostics

Knowing how to tell which TPMS sensor is bad with just the dashboard is convenient for everyday monitoring.

Common Causes of TPMS Sensor Failure and Prevention

Causes:

- Battery depletion (approx. 70% of failures)

- Physical damage (tire change or road impact)

- Signal interference (security screws or electronics)

- Corrosion or aging of valve stems

Maintenance and Replacement Tips:

- Replace in pairs: front or rear sensors simultaneously

- Register new sensors: update ECU IDs with a diagnostic tool after replacement

- Replace valve stems: prevent slow leaks and maintain airtightness

- Ensure compatibility: check frequency (315 MHz / 433 MHz) and communication protocol

- Professional verification: confirm successful sensor relearn after installation

- Preventive check: inspect TPMS sensors professionally after 6 years or 80,000 km

Frequently Asked Questions (FAQ)

Q1: Does TPMS light always mean a sensor is bad?

❌ Not necessarily. It could be low tire pressure, spare tire issue, or system not reset.

Q2: Can I replace the TPMS battery myself?

❌ No. Most sensors are sealed units; battery cannot be replaced. Replace the entire sensor if battery fails.

Q3: Do I need to replace sensors when changing tires?

✅ Only if sensors are near end-of-life or hub frequencies differ. Learn more about handling TPMS sensors during tire replacement

Q4: Can I drive with a TPMS warning light on?

⚠️ Only short distances at low speed to a workshop. Long-distance driving is unsafe. Check actual tire pressure first.

Q5: Does temperature affect TPMS readings?

✅ Yes. Tire pressure drops ~1 PSI per 10°F decrease. This is normal physics, not sensor failure.

Q6: How should I maintain TPMS sensors?

- Inspect system annually or every 5,000–6,000 miles

- Replace paired sensors together

- Ensure frequency and protocol match when replacing

- Perform system reset and sensor relearn for accurate data

Professional Tip: These methods apply to most common vehicles. BMW, Mercedes, and other brands may have unique systems. Refer to your owner’s manual or authorized service center.

Conclusion

You can determine how to tell which TPMS sensor is bad using three main methods:

- Diagnostic computer – most precise, ideal for professionals

- TPMS activation tool – fast and effective for advanced users

- Dashboard observation & DIY check – convenient for routine monitoring

✅ Regularly check tire pressure, replace faulty sensors promptly, and visit a professional workshop if necessary. Keeping the TPMS system operational is essential for vehicle safety. Mastering how to tell which TPMS sensor is bad ensures both safety and efficiency.

Authoritative References:

- NHTSA TPMS Safety Guide

- SAE J2657 TPMS Communication Protocol Standard

- GB 7258-2017 Motor Vehicle Operational Safety Requirements